Signal analysis and condition monitoring

Modares Vibration and Acoustics Technology Company with experienced manpower with the ability to provide services in the fields of condition monitoring , analysis and processing of vibration signals (Signal analysis), denoising , SVM learning machine, emergence detection (Novelty Detection) and …. The following is a brief description of each of these.

Condition Monitoring

Condition monitoring is based on checking and monitoring the current status of the machine in operation and predicting its future status. This means that information about the internal condition of the working machine can be obtained from outside. Condition monitoring is one of the main components of predictive maintenance

Different methods of status monitoring

Vibration analysis is the most important and most widely used.

Vibration analysis

Analysis and processing of vibration signals (Signal Processing)

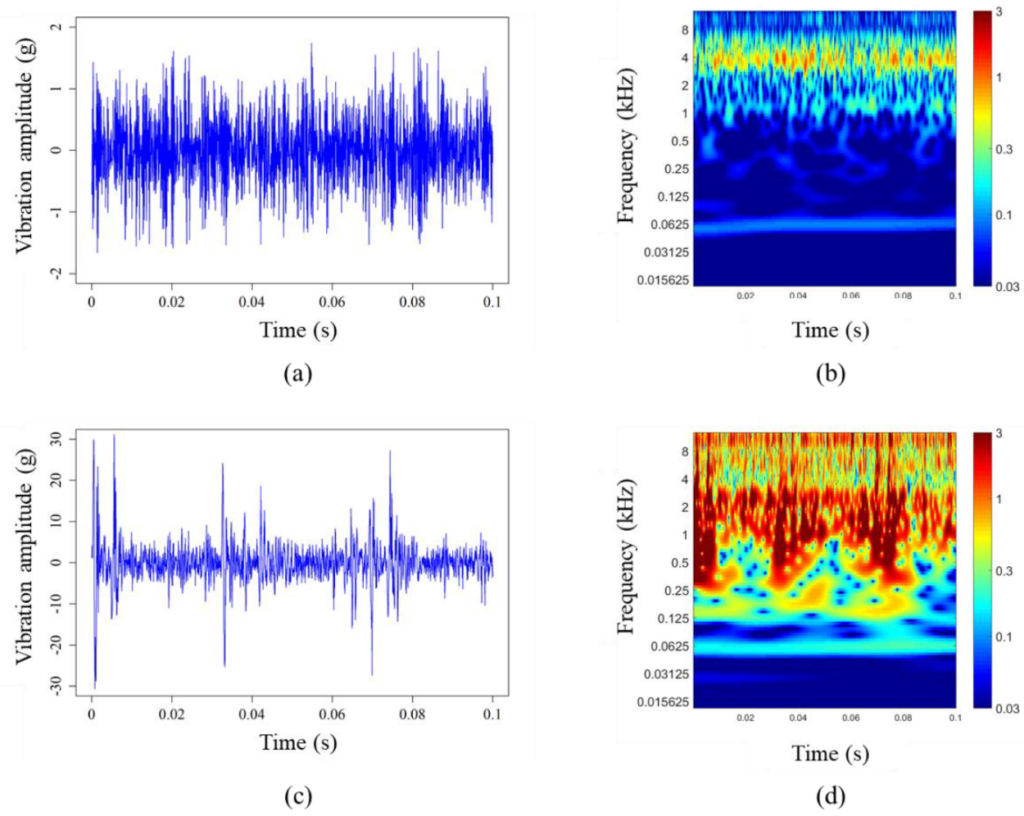

In the case of rotating machines, the use of vibration signals such as acceleration, speed and displacement because these signals contain dynamic information about the state of the machine; It is effective in identifying and distinguishing between various defects. Methods of analysis and troubleshooting in rotating machines with the help of vibrating signals can be divided into the following three categories:

- Time domain analyzes

- Frequency domain analyzes

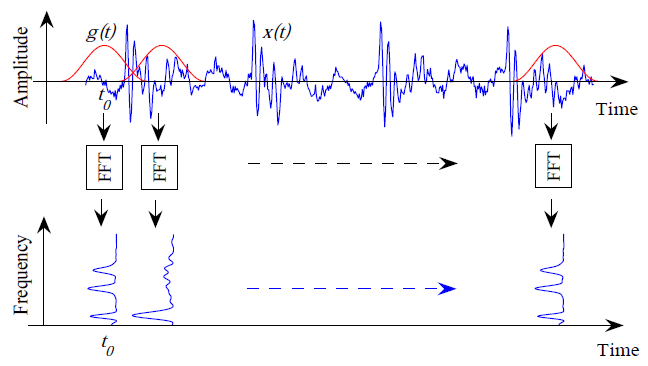

- Time-frequency domain analyzes

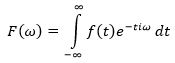

Time domain analyzes are directly based on time waveform. Traditional time domain analysis calculates characteristic features in the form of statistical descriptions of time waveform signals. Features such as mean, peak, crest coefficient, and high-order statistics such as root mean square, skewness, kurtosis, and more. These features, mostly called time domain features, are used with limited ability to detect local defects. Common time domain analytical approaches, such as simultaneous averaging, and the self-reversing model, are widely used to troubleshoot rotary machines. Frequency domain analyzes or spectral analyzes are generally performed by Fourier transform. Fourier analysis converts a time domain signal f (t) to a frequency domain; So that the generated spectrum F (ω) includes all the signal frequency content (base and harmonic) which is defined as the following relation:

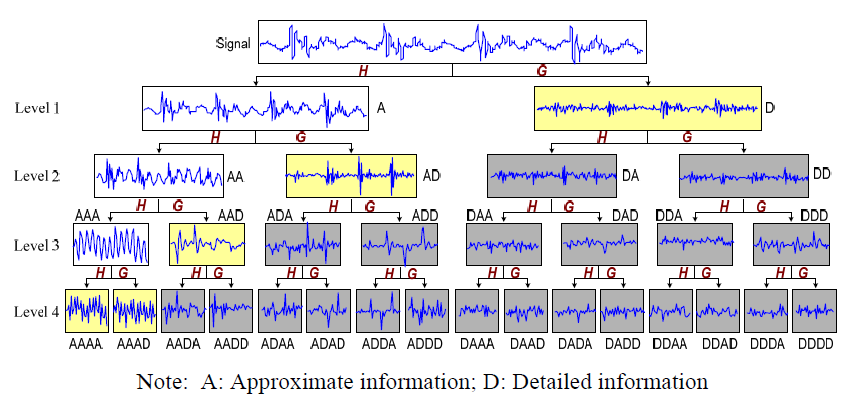

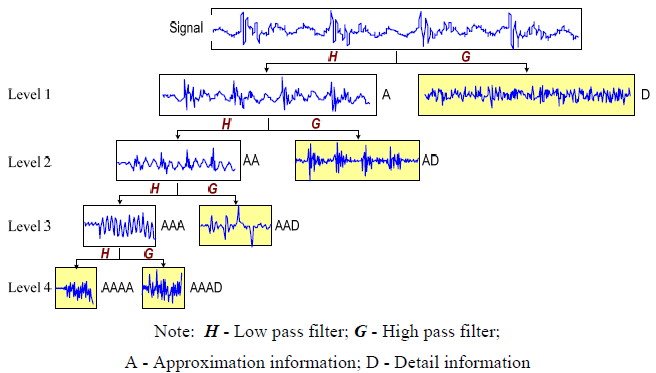

Wavelet transform is done in the following 3 ways:

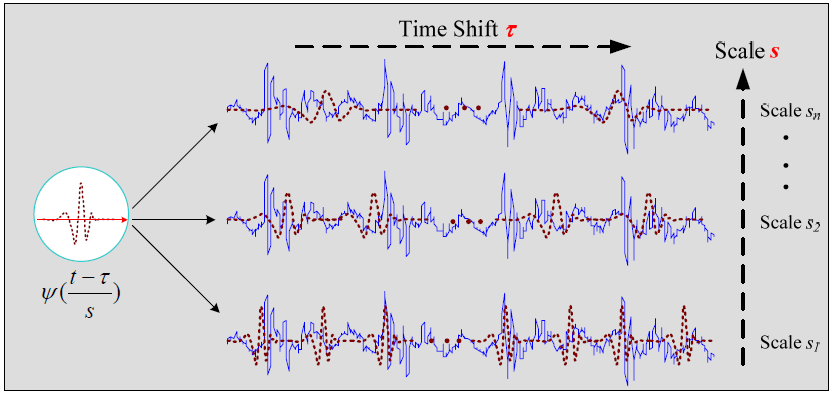

1) Continuous Wavelet Converter (CWT)

2) Discrete wavelet transform

3) Alternative by Wavelet Packets (WPD)